Three-station gantry loading and unloading machine

Category:

keyword:

Product Description

- 产品描述

-

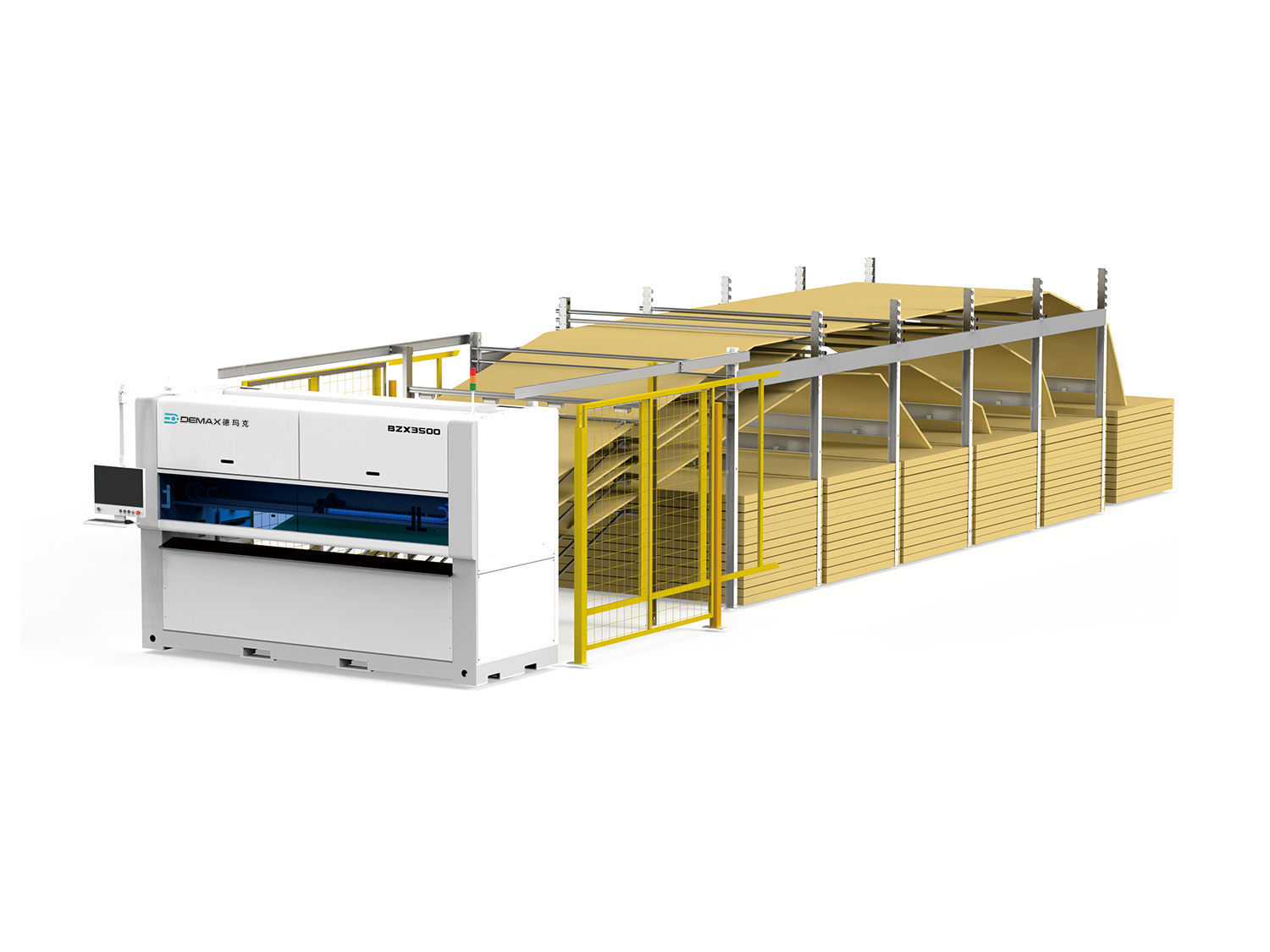

Three-Station Gantry Loading and Unloading Machine

Introduction

In the ever-evolving world of manufacturing and logistics, efficiency and precision are paramount. One of the innovations that have emerged to address these needs is the three-station gantry loading and unloading machine. This sophisticated piece of equipment has transformed the way goods are handled in various industries, from automotive to electronics. In this article, we will explore the design, functionality, advantages, and applications of the three-station gantry loading and unloading machine.

Design and Functionality

The three-station gantry loading and unloading machine is designed to streamline the process of transferring materials between different points in a production line or warehouse. The term "gantry" refers to a structure that spans an area, providing a framework for the movement of loads. In this case, the gantry consists of a robust framework that supports a crane-like mechanism capable of lifting and moving heavy items.

The machine typically features three distinct stations: the loading station, the unloading station, and the intermediate processing station. Each of these stations plays a crucial role in the overall operation. The loading station is where raw materials or products are placed onto the machine, while the unloading station is where finished goods are removed. The intermediate station allows for processing, sorting, or inspection of items as they pass through the system.

The gantry mechanism itself is equipped with advanced automation technology, including sensors and programmable logic controllers (PLCs). These components enable precise control over the machine's movements, ensuring that loads are handled safely and efficiently. The ability to program specific tasks and sequences also allows for customization based on the unique needs of a production line.

Advantages of Three-Station Gantry Machines

The implementation of a three-station gantry loading and unloading machine offers several advantages to businesses. Firstly, it significantly increases operational efficiency. By automating the loading and unloading process, companies can reduce the time spent on manual labor, allowing workers to focus on more value-added tasks. This not only speeds up production but also enhances overall productivity.

Secondly, the three-station design improves flexibility. Businesses often deal with varying types of products and materials. The ability to customize the machine's operations allows it to handle different items without the need for extensive reconfiguration. This adaptability is particularly beneficial in industries where product lines frequently change.

Moreover, safety is enhanced with the use of a gantry machine. The automation of loading and unloading reduces the risk of workplace injuries associated with manual handling. Additionally, the use of sensors and safety features ensures that the machine operates within safe parameters, protecting both workers and equipment.

Applications Across Industries

The versatility of the three-station gantry loading and unloading machine makes it applicable across various industries. In the automotive sector, for instance, these machines are employed to handle components and assemblies with precision. They can load parts onto assembly lines and unload finished vehicles efficiently, contributing to faster production cycles.

In the electronics industry, where components can be delicate and require careful handling, gantry machines provide a reliable solution. They can be programmed to handle sensitive items, ensuring that they are loaded and unloaded without damage. This capability is crucial in maintaining quality standards and minimizing waste.

The packaging and distribution sector also benefits from the use of three-station gantry machines. They can streamline the process of loading products into shipping containers or onto pallets, significantly reducing the time required for order fulfillment. As e-commerce continues to grow, the demand for efficient loading and unloading solutions becomes increasingly important.

Future Trends and Innovations

As technology continues to advance, the three-station gantry loading and unloading machine is expected to evolve further. One of the key trends is the integration of artificial intelligence (AI) and machine learning. These technologies can enhance the machine's ability to learn from past operations, optimizing performance and reducing downtime.

Another trend is the development of collaborative robots, or cobots, that can work alongside human operators. This hybrid approach allows for increased flexibility and efficiency, as cobots can assist with tasks that require precision while humans handle more complex responsibilities.

Additionally, advancements in sensor technology will likely lead to improved safety features and real-time monitoring capabilities. This will enable operators to receive instant feedback on machine performance and potential issues, allowing for proactive maintenance and reducing the risk of breakdowns.

Conclusion

The three-station gantry loading and unloading machine represents a significant advancement in material handling technology. Its design, functionality, and advantages make it an invaluable asset in various industries, driving efficiency and safety in production and logistics processes. As businesses continue to seek ways to optimize their operations, the role of such machines will only grow in importance. With ongoing innovations on the horizon, the future of loading and unloading technology looks promising, ensuring that industries can meet the demands of an increasingly competitive marketplace.

Related Downloads

-

File size: 101.9MB

Message Inquiry

We attach great importance to your opinions and consultations. If you have any inquiries about our products and services, please fill out the following form and we will contact you as soon as possible.

Jiangxi Demark Intelligent Equipment Co., Ltd. Is A High-Tech Enterprise Specializing In The Research And Development, Production, Sales, And Service Of Automated Intelligent Equipment

Mobile/wechat:

Email:

Address

No. 19 Meiyun Road, High-tech Industrial Development Zone, Yingtan City, Jiangxi Province

Products