Large span gantry loading and unloading machine

Category:

keyword:

Product Description

- 产品描述

-

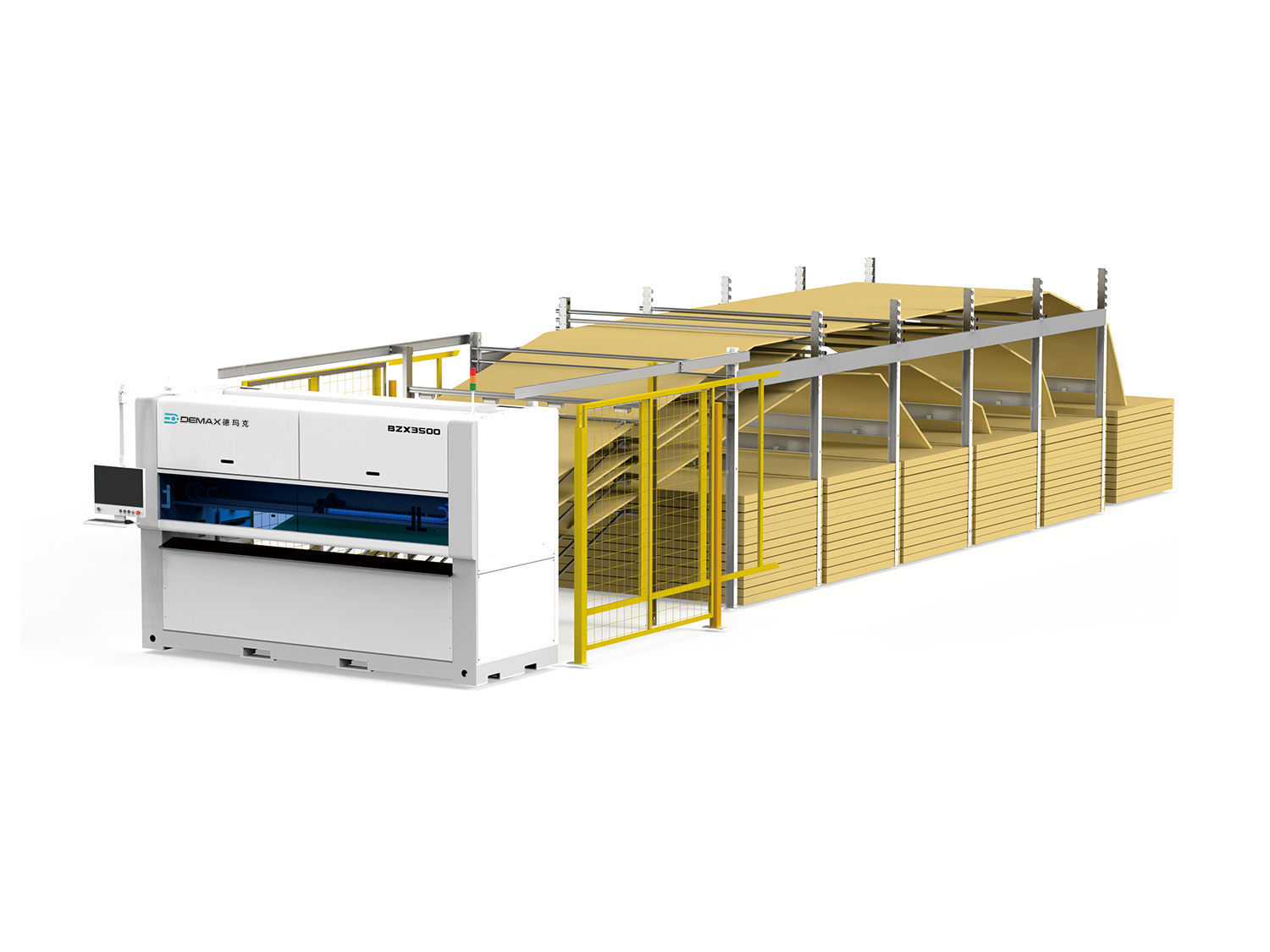

**Large Span Gantry Loading and Unloading Machine**

In the realm of industrial automation and material handling, the large span gantry loading and unloading machine stands out as a pivotal innovation. This sophisticated equipment is designed to streamline the processes of loading and unloading heavy materials, enhancing efficiency and safety in various sectors such as manufacturing, construction, and logistics. This article delves into the features, advantages, applications, and future prospects of large span gantry loading and unloading machines.

**Understanding the Large Span Gantry Machine**

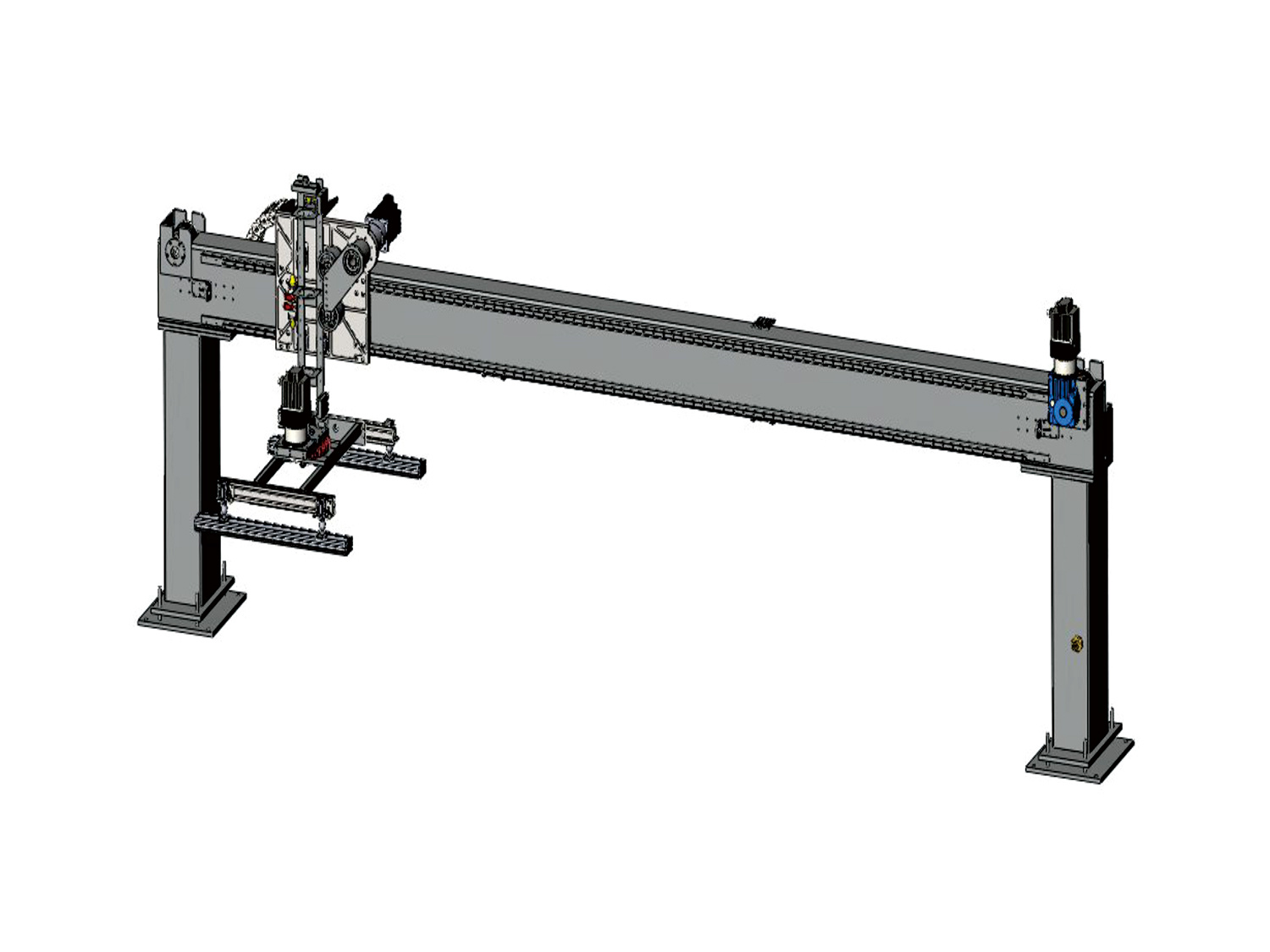

A large span gantry loading and unloading machine typically consists of a robust frame structure that spans a considerable distance, allowing it to cover large areas. The machine is equipped with a hoisting mechanism, often featuring electric or hydraulic systems, which enables it to lift and move heavy loads. The gantry design allows for stability and support, making it suitable for handling oversized materials that would be challenging to manage with conventional lifting equipment.

The structure of the gantry is usually made from high-strength materials such as steel, ensuring durability and the ability to withstand significant operational stresses. The machine can be configured in various ways, including fixed, mobile, or semi-mobile designs, depending on the specific needs of the application.

**Key Features**

One of the defining characteristics of large span gantry machines is their extensive reach. With spans that can exceed several meters, these machines can efficiently handle materials in large production facilities or outdoor environments.

Another critical feature is their versatility. Many gantry machines can be equipped with different attachments such as clamps, hooks, or forks, allowing them to handle a variety of loads, from steel beams to containers. This adaptability makes them invaluable in industries where the nature of the materials being handled can vary significantly.

Additionally, modern gantry machines are often integrated with advanced control systems, including programmable logic controllers (PLCs) and user-friendly interfaces. This technological integration enhances operational precision and allows for the automation of loading and unloading processes, reducing the risk of human error and improving overall productivity.

**Advantages of Large Span Gantry Machines**

The implementation of large span gantry loading and unloading machines brings several advantages to industrial operations.

First and foremost, they significantly enhance operational efficiency. By automating the loading and unloading processes, companies can reduce the time required to move materials, leading to faster production cycles and increased throughput. This efficiency is particularly beneficial in high-demand environments where time is a critical factor.

Safety is another crucial advantage. Large span gantry machines are designed with safety features such as overload protection, emergency stop buttons, and fail-safe mechanisms. By minimizing manual handling, they reduce the risk of accidents and injuries associated with lifting heavy materials. This focus on safety not only protects workers but also helps companies avoid costly downtime due to workplace incidents.

Moreover, these machines contribute to cost savings in the long run. While the initial investment may be significant, the increased efficiency and reduced labor costs often lead to a rapid return on investment. Additionally, their durability and low maintenance requirements further enhance their cost-effectiveness over time.

**Applications Across Industries**

The versatility of large span gantry loading and unloading machines allows them to find applications across various industries.

In the manufacturing sector, they are commonly used for moving heavy components between production lines, facilitating assembly processes, and managing inventory. Their ability to handle large loads makes them ideal for industries such as automotive, aerospace, and heavy machinery manufacturing.

In the construction industry, large span gantry machines are essential for lifting and positioning structural elements like steel girders and concrete panels. Their mobility and reach enable them to operate effectively on construction sites, where space may be limited.

The logistics and shipping industries also benefit from these machines, as they are used to load and unload containers from ships, trucks, and trains. Their efficiency in handling bulk materials and oversized loads makes them a crucial component in supply chain operations.

**Future Prospects**

As technology continues to advance, the future of large span gantry loading and unloading machines looks promising. Innovations such as artificial intelligence (AI) and the Internet of Things (IoT) are expected to further enhance the capabilities of these machines.

AI can improve operational efficiency by optimizing load distribution, predicting maintenance needs, and enabling real-time monitoring of machine performance. IoT integration can facilitate better communication between machines, allowing for coordinated operations in automated environments.

Sustainability is also becoming a focal point in industrial design. Future gantry machines may incorporate energy-efficient technologies and environmentally friendly materials, aligning with global efforts to reduce carbon footprints and promote sustainable practices.

**Conclusion**

In conclusion, large span gantry loading and unloading machines are indispensable tools in modern industrial operations. Their robust design, versatility, and efficiency contribute significantly to improving productivity and safety across various sectors. As technology evolves, these machines will continue to play a vital role in shaping the future of material handling, paving the way for more automated, efficient, and sustainable industrial processes. Embracing these innovations will undoubtedly empower industries to meet the growing demands of a rapidly changing market landscape.

Related Downloads

-

File size: 28.1MB

Message Inquiry

We attach great importance to your opinions and consultations. If you have any inquiries about our products and services, please fill out the following form and we will contact you as soon as possible.

Jiangxi Demark Intelligent Equipment Co., Ltd. Is A High-Tech Enterprise Specializing In The Research And Development, Production, Sales, And Service Of Automated Intelligent Equipment

Mobile/wechat:

Email:

Address

No. 19 Meiyun Road, High-tech Industrial Development Zone, Yingtan City, Jiangxi Province

Products