Frame gantry loading and unloading machine

Category:

keyword:

Product Description

- 产品描述

-

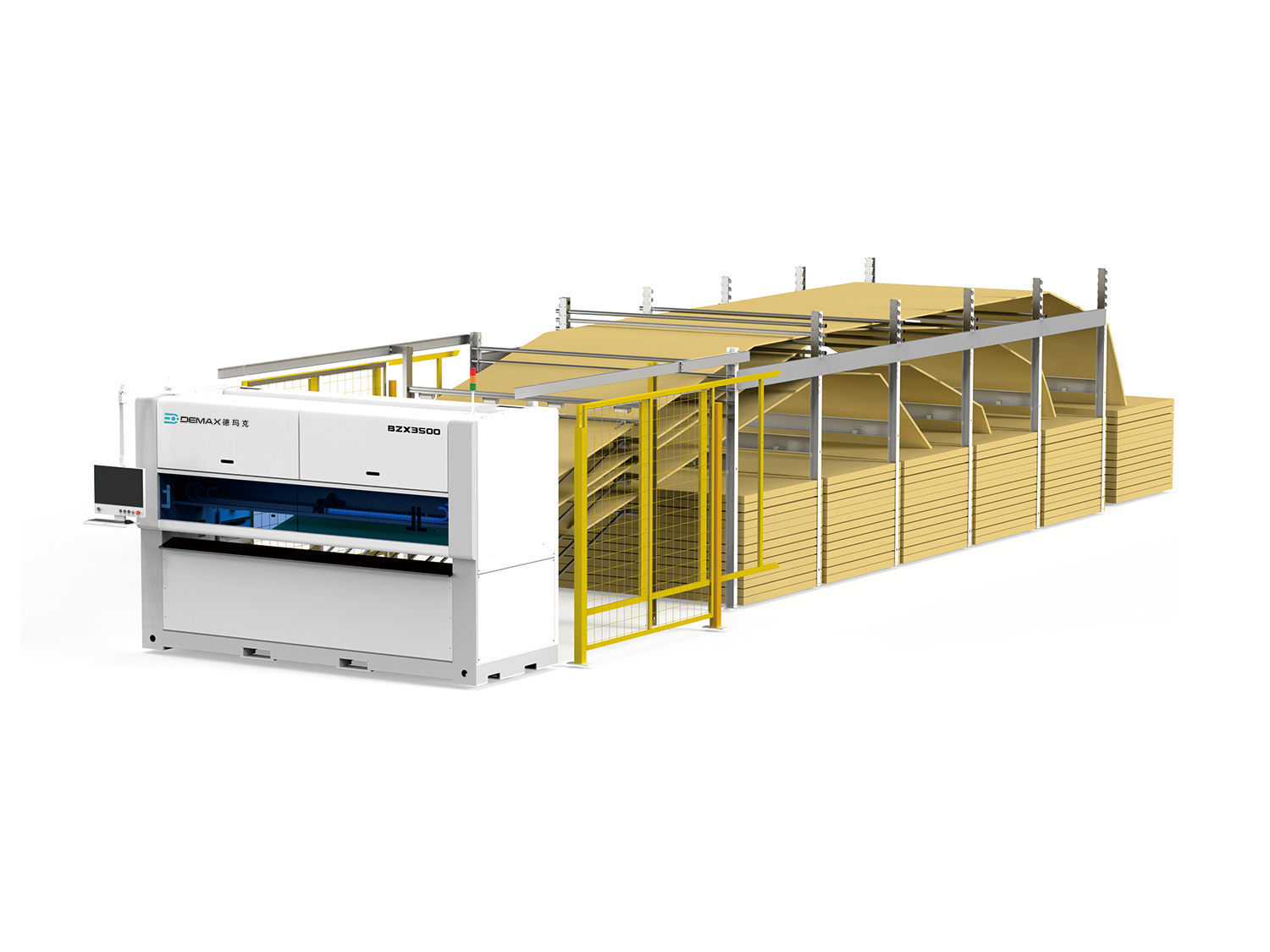

Frame Gantry Loading and Unloading Machine

In the realm of modern industrial automation, efficiency and precision are paramount. Among the many innovations that have emerged to enhance productivity, the large span gantry loading and unloading machine stands out as a pivotal technology. This machine not only streamlines the process of handling heavy materials but also significantly reduces labor costs and minimizes the risk of workplace accidents. In this article, we will explore the design, functionality, applications, and benefits of large span gantry loading and unloading machines.

**Design and Structure**

Large span gantry loading and unloading machines are characterized by their robust structure and versatile design. Typically, these machines consist of a horizontal beam supported by two vertical legs, creating a stable framework that can traverse large areas. The horizontal beam is equipped with a hoisting mechanism, such as a crane or a trolley, allowing for the lifting and moving of heavy loads.

The materials used in the construction of these machines are critical for their performance and longevity. High-strength steel is commonly employed to ensure durability and resistance to wear and tear. Additionally, advanced engineering techniques are utilized to optimize the design, ensuring that the machine can handle the intended load capacity without compromising safety.

**Functionality and Operation**

The primary function of a large span gantry loading and unloading machine is to facilitate the movement of heavy materials within a designated area. This is achieved through a combination of vertical lifting and horizontal movement. Operators can control the machine using a remote control or a centralized control panel, allowing for precise maneuvering of loads.

The hoisting mechanism is equipped with various attachments, such as hooks, clamps, or magnet systems, depending on the type of materials being handled. This versatility makes the gantry machine suitable for a wide range of applications, from loading and unloading shipping containers to moving large industrial components.

**Applications in Various Industries**

Large span gantry loading and unloading machines are utilized across multiple industries, showcasing their versatility and effectiveness. In the manufacturing sector, these machines are often employed to move heavy parts and materials within factories, enhancing workflow efficiency. They are particularly valuable in assembly lines, where precision and speed are essential.

In the construction industry, gantry machines play a crucial role in lifting and positioning heavy building materials, such as steel beams and concrete panels. Their ability to operate in confined spaces makes them ideal for construction sites where traditional cranes may not be feasible.

The shipping and logistics sector also benefits from large span gantry machines, particularly in container terminals. These machines can efficiently load and unload shipping containers from trucks and vessels, significantly reducing turnaround times and increasing productivity.

**Advantages of Using Large Span Gantry Machines**

The adoption of large span gantry loading and unloading machines offers numerous advantages for businesses. One of the most significant benefits is the reduction in labor costs. By automating the loading and unloading process, companies can minimize the need for manual labor, allowing workers to focus on more skilled tasks.

Safety is another critical advantage. Heavy lifting operations inherently carry risks, but the use of gantry machines mitigates these hazards by reducing the need for workers to manually handle heavy loads. This leads to fewer workplace injuries and accidents, promoting a safer working environment.

Moreover, the efficiency gained through the use of these machines can lead to increased production rates. With faster loading and unloading times, businesses can optimize their operations, ensuring that materials are moved swiftly and accurately. This not only enhances productivity but also improves overall supply chain management.

**Future Trends and Innovations**

As technology continues to advance, the future of large span gantry loading and unloading machines looks promising. Innovations such as the integration of smart technology and automation are expected to revolutionize the way these machines operate. For instance, the incorporation of sensors and artificial intelligence can enable real-time monitoring of load conditions, enhancing safety and efficiency.

Furthermore, advancements in materials science may lead to the development of lighter yet stronger materials for machine construction. This could result in even more efficient designs, allowing for greater mobility and flexibility in various operational environments.

**Conclusion**

In conclusion, large span gantry loading and unloading machines represent a significant advancement in industrial automation. Their robust design, versatile functionality, and wide-ranging applications make them an invaluable asset across multiple sectors. By enhancing efficiency, reducing labor costs, and promoting workplace safety, these machines play a crucial role in modernizing operations and driving productivity. As technology continues to evolve, the future of large span gantry machines promises even greater innovations, further solidifying their position as a cornerstone of industrial automation.

Related Downloads

-

File size: 28.1MB

Message Inquiry

We attach great importance to your opinions and consultations. If you have any inquiries about our products and services, please fill out the following form and we will contact you as soon as possible.

Jiangxi Demark Intelligent Equipment Co., Ltd. Is A High-Tech Enterprise Specializing In The Research And Development, Production, Sales, And Service Of Automated Intelligent Equipment

Mobile/wechat:

Email:

Address

No. 19 Meiyun Road, High-tech Industrial Development Zone, Yingtan City, Jiangxi Province

Products